Recycled sand and plastic waste are used to make this sustainable brick! - Yanko Design

Did y'all know that the construction industry really contributes more to global warming than the aviation industry? Construction is responsible for 39% of the globe'south CO2 emissions while aviation is responsible for two% and that means we need a sustainable building material before we demand electrical airplanes. Rhinoceros Machines is an Indian company that has recently launched a sustainable culling to the traditional brick called the silica plastic block in collaboration with architectural firm R+D Studio.

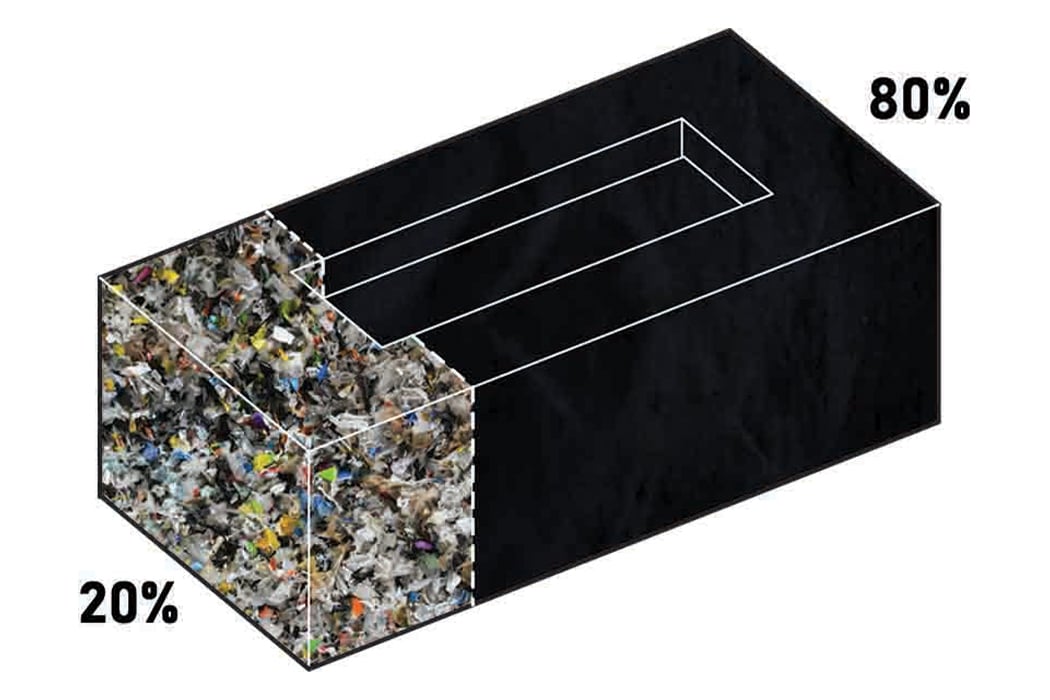

We've seen mushrooms turn into bricks and now we are seeing this brick made of 80% recycled sand waste/foundry dust and 20% mixed plastic waste. The SPB (silicone plastic cake) was created to curb the gigantic dust waste from construction that contributes to India's pollution levels that are already chancy in major cities. The projection started with a goal of producing zero waste from the sand reclamation establish in the Rhino Machines foundry institute. There were many experiments before landing on this ratio, initially foundry dust was used in cement-bonded fly ash bricks (7-ten% waste material recycled) and dirt bricks (fifteen% waste product recycled). This production procedure was reliant on natural supplies such as cement, fertile soil, and water which wouldn't justify the team's criteria of creating something that was more environmentally friendly. After multiple trials and research, the solution of bonding sand/foundry dust with plastic was born. Since it is fabricated out of waste, the toll of production is relatively low and Rhino Machines is working on an ecosystem solution so that the foundries across the state tin develop and distribute the SPBs within their zones.

The team used mixed plastic waste as a bonding agent which reduced the need for water during mixing and thereafter curing is completely eliminated. These sustainable bricks would be directly used after cooling downward from the molding process. Over four months the team approached hospitals, societies, individuals, social organizations, and the local municipal corporations to provide clean plastic. A total of six tonnes of plastic waste matter and sixteen tonnes of dust + sand from the foundry industry were collected, set to be recycled. The SPB bricks were 2.5 times stronger than the regular ruby clay bricks and used eighty% lesser natural resources as well – now you can build a stronger dwelling house that also lets your domicile planet be strong. Amend to employ that plastic in bricks than to put it in the sea!

Designers: Rhino Machines and R+D Studio

Source: https://www.yankodesign.com/2020/06/15/recycled-sand-and-plastic-waste-are-used-to-make-this-sustainable-brick/

0 Response to "Recycled sand and plastic waste are used to make this sustainable brick! - Yanko Design"

Post a Comment